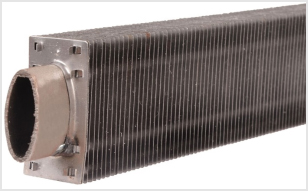

Elliptical Finned Tube

Thermotech Industries (India) Private Limited has expertise in manufacturing and supplying of Finned Tubes and Heat Exchangers with constant up gradation in our products as per customers requirement.

We follow the latest ASME codes for designing Heat Exchangers and are well experienced with the standards and requirement of many Industries including Chemical, Textile, Power Generation and Process Houses.

We are capable of manufacturing any kind of Heat exchanger with the support of our strong work force along with experienced consultants of this field.

We also manufacture range of Condensers like Finned Tube Type Alternator Cooler, Plate Fin Type Cooler for Sulphonation Plant, Plate Fin Cooler for Galvanizing Line

Elliptical Finned tube

An ELLIPTICAL FINNED TUBES is one of the particular type Finned Type used in Fin Type Heat Exchangers to improve thermal efficiency by increasing the surface area. These tubes are commonly used in Steam OR Thermic Fluid heat exchangers, boilers, condensers, and various industrial applications where efficient heat transfer is critical and there is a need of Compact design.

Key Features of Elliptical finned tube :

- Elliptical Shape: Unlike traditional round tubes, elliptical tubes have a streamlined shape that reduces airflow resistance. This aerodynamic design enhances the heat transfer process while lowering the air side pressure drop, making them more energy-efficient. The shape allows more fin contact, enhancing heat exchange efficiency between the fluid inside the tube and the surrounding air.

- Fins: The fins, attached perpendicularly to the tube, further increase the surface area available for heat exchange. The combination of an elliptical shape and extended fins increases the heat transfer surface area, leading to better thermal performance than circular tubes. The elliptical shape of the tube optimizes the distribution of the fins, leading to improved heat transfer compared to round finned tubes.

- Corrosion Resistance :Finned tubes are often made from materials like stainless steel, copper, or aluminum, offering excellent resistance to corrosion, which is essential for longevity, especially in harsh environments.

- Structural Strength : The elliptical shape provides better structural integrity, especially in high-pressure applications, reducing the risk of damage or failure compared to circular tubes.

- Reduced Fouling : The smooth airflow over the elliptical surface results in less dirt and debris buildup, minimizing fouling and reducing the need for frequent maintenance.

Typical Size for Elliptical finned tube :

- Elliptical Tube Size - 35mm x 15mm - Thickness As per requirement

- Fin Size - 55mm x 26mm / 55mm x 25mm

- Fins / Inch - 7 / 8 / 9 Fins Per Inch

Material of Construction for Elliptical finned tube :

- Tube Material - CS / SS / Copper

- Fin Material - CS / CS - Galvanized / SS / Copper / Aluminum

Advantages of Elliptical finned tube :

Increased heat transfer efficiency:

- Increased Surface Area: The elliptical shape provides a larger surface area compared to round tubes of the same cross-sectional area, improving heat transfer efficiency.

- Turbulence Promotion: The streamlined shape promotes turbulence in the fluid flow, which enhances heat transfer by preventing the formation of a boundary layer.

- Better Contact with Air/Gas: Elliptical tubes maintain better contact with the surrounding air or gas, optimizing convective heat transfer.

Reduced pressure drop:

- The streamlined profile of elliptical tubes reduces the pressure drop across the heat exchanger, which is beneficial for energy savings in air handling and circulation systems.

- Lower pressure drop reduces the energy required to move fluids, which can improve overall system efficiency and reduce operational costs.

Aerodynamic Benefits:

- In applications involving airflow (e.g., air-cooled heat exchangers), the elliptical tube shape provides better aerodynamic properties. This leads to reduced drag and can help improve airflow performance, making it more efficient in cooling or heating applications.

Applications of Elliptical finned tube :

Elliptical finned tubes are widely used in industries that require efficient heat transfer, particularly where space constraints exist, or where improved aerodynamic performance is needed. The elliptical shape of the tubes provides a larger surface area for heat transfer while reducing air resistance and pressure drop, making them highly efficient.

Marine / Rice Mills / Paper Boards / Power Houses / Chemical / Steam Radiators / Thermic Fluid Radiators / Air Cooled Exchangers

Air-Cooled Heat Exchangers : Used in industries such as oil refineries, petrochemicals, and power plants to dissipate heat from process fluids. The elliptical shape provides higher aerodynamic efficiency, reducing energy consumption for air movement.

Power Plants : Applied in boilers, condensers, and economizers to optimize heat recovery from flue gases or steam. Their design minimizes fouling and pressure loss in steam and air handling.

Marine Industry : Used in Shipboard HVAC Systems For maintaining proper ventilation and air conditioning in marine vessels. Seawater Heat Exchangers used in desalination plants or cooling systems on ships and oil rigs. Oil and Gas Offshore Platforms for process cooling and heating applications.

Rice Mills : Used in Rice mills, for Paddy drying, husk-fired boilers, or other thermal processing units. Typically made of materials like stainless steel or aluminum, they are resistant to corrosion and can withstand high temperatures.

Paperboard Industry : In the production of paper and paperboards, the drying process is critical. Elliptical finned tubes are used in heat exchangers to supply hot air or transfer heat to the drying cylinders. They capture heat from exhaust gases or other heat sources and use it for preheating air or water, optimizing energy usage in paperboard mills.

Chemical Industry : Widely used in the chemical industry for heat transfer applications, such as in heat exchangers and air-cooled heat exchangers.

Steam Radiators : Used in HVAC systems for heating large spaces. Air Preheaters In boilers or steam generation systems to recover waste heat. Industrial Dryers where high thermal efficiency is needed for drying processes. Chemical and Petrochemical Heat Exchangers for Handling high-temperature or aggressive media.

Thermic Fluid Radiators : Widely used in systems where thermic fluids transfer heat to processes such as drying, heating, or thermal oil circulation. Used in waste heat recovery systems and thermal energy management in power plants. effective in industries like chemicals, food processing, and textile manufacturing.

These tubes are favored in any industry where high-efficiency heat transfer, compact design, and energy savings are required. Their aerodynamic design reduces air resistance, making them well-suited for applications that involve air or gas flow.