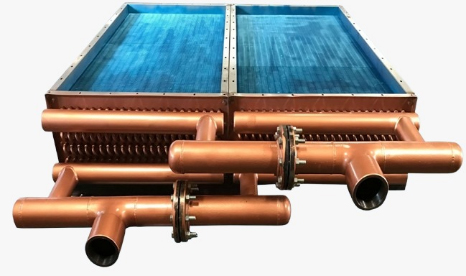

Plate Fin Type Cooler for Sulphonation Plant

Thermotech Industries (India) Private Limited has expertise in manufacturing and supplying of Finned Tubes and Heat Exchangers with constant up gradation in our products as per customers requirement.

We follow the latest ASME codes for designing Heat Exchangers and are well experienced with the standards and requirement of many Industries including Chemical, Textile, Power Generation and Process Houses.

We are capable of manufacturing any kind of Heat exchanger with the support of our strong work force along with experienced consultants of this field.

We also manufacture range of Condensers like Finned Tube Type Alternator Cooler, Plate Fin Type Cooler for Sulphonation Plant, Plate Fin Cooler for Galvanizing Line

Plate Fin Type Cooler for Sulphonation Plant:

In a Sulphonation plant, plate fin type coolers are often used as part of the cooling system for cooling Utility Air or Process gases. Sulphonation processes typically involve the use of sulfur trioxide (SO₃) gas, which reacts with organic compounds like hydrocarbons to produce sulfonic acids, sulfonates, or sulfates. Since these reactions are exothermic (they release a lot of heat), a cooling system is essential to control the reaction temperature and avoid degradation of the product. Plate Fin Coolers are typically designed and Fins are coated with special Thermoguard Coating to make it resistant chemical fumes.

Features of Plate Fin Type Coolers in Sulphonation Plants:

- • Compact and Efficient Design: Plate fin heat exchangers have a high surface area to volume ratio, making them compact yet highly efficient for heat transfer. This is crucial in Sulphonation plants where space is often limited.

- • Temperature Control: Maintaining the correct temperature is vital during the Sulphonation process to ensure product quality. Plate fin coolers help regulate the temperature by efficiently removing the heat generated during the reaction.

- • Corrosion Resistance: The materials used in the cooler, like Copper or aluminum, are often chosen for their resistance to corrosion, as sulfur compounds can be highly corrosive. Copper Tubes and Aluminium Fins are treated and Coated with special corrosive resistant coatings to improve life in a corrosive atmosphere.

- • Multiple Fluids Handling: Plate fin type coolers can handle different fluids, allowing the use of various cooling media such as Cooling water, Chilled Water, Glycol, or other coolants.

- • Easy Maintenance and Cleaning: Due to their modular construction, plate fin coolers can be easier to inspect, maintain, and clean, which is important in environments where regular upkeep is necessary to prevent fouling.

- • Customizable Design: Depending on the specific requirements of the Sulphonation process, the cooler can be customized to handle varying flow rates, temperatures, and pressures.

- • Energy Efficiency: These coolers provide high efficiency in heat exchange while minimizing energy consumption, which is beneficial in reducing operational costs in a chemical plant.

Material of Construction For Plate Fin Cooler:

- Tube Material - Copper / Cu-Ni / Brass

- Fin Material - Aluminium / Copper

- Body - SS - As per Requirement

- Surface Coatings

- Fins - Thermoguard Coating / Blue Fin / Anodized Fins

- Copper - PU Copper Coatings

Advantages of Plate Fin Type Coolers in Sulphonation Plants:

Plate fin type coolers offer several advantages for Sulphonation plants, where precise temperature control is critical. These advantages make plate fin type coolers a favorable choice for enhancing the efficiency and effectiveness of cooling operations in Sulphonation plants.

- • High Heat Transfer Efficiency: Plate fin coolers have a large surface area due to their design, which enhances heat transfer efficiency. This allows for effective cooling even at higher flow rates.

- • Versatility: Plate fin coolers can handle a variety of fluids, including gases and liquids, making them suitable for different cooling applications in Sulphonation processes.

- • Low Pressure Drop: The design minimizes the resistance to fluid flow, resulting in lower pressure drops. This helps in maintaining energy efficiency and reducing pump costs.

- • Corrosion Resistance: They can be constructed from materials that resist corrosion, which is particularly important in Sulphonation plants where reactive chemicals are involved.

- • Reduced Fouling: The design can help reduce fouling, which is the accumulation of unwanted material on solid surfaces. This leads to lower maintenance and longer operational life.

- • Modular Design: Plate fin coolers can be designed in modules, allowing for easy scalability and customization based on the specific needs of the Sulphonation process.

- • Improved Process Control: Their efficiency in heat exchange allows for better temperature control, which is crucial for optimizing Sulphonation reactions and improving product quality.

Applications of Plate Fin Type Coolers in Sulphonation Plants:

Plate fin type coolers are widely used in Sulphonation plants due to their efficient heat exchange capabilities. In Sulphonation plants, plate fin type coolers play a crucial role in managing heat and ensuring efficient process operation. Their compact design, high efficiency, and adaptability make them an excellent choice for thermal management in these industrial processes.

Chemical Plants / Power Houses / Oil & Gas / Pharma Industries / Fertilizers / Sulphonation